- Ranipet

- Sivakasi

- Karur

- Udhagamandalam

- Hosur

Our advance 4-20mA vibration transmitters or loop powered sensors, are engineered for use with the latest PLC (programmable logic controller), BMS (building management system), or SCADA (supervisory control and data acquisition) technologies, offering sophisticated solutions for condition monitoring and preventative maintenance.

The purpose of the 4-20 mA analog current loop is to transmit the signal from an analog vibration sensor over a distance in the form of a current signal. ROKADE's loop power sensors output a 4-20 mA current that is proportional to the overall vibration of the equipment or machinery they are monitoring. This output current has a range of 4-20 mA (4 mA normally representing the sensor's zero-level output, and 20 mA representing the sensor's full-scale output).

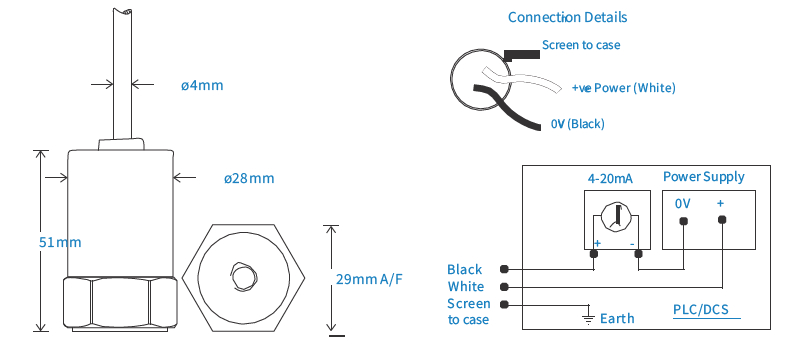

Only two wires are required to send the current signal and also supply power to the sensor. A loop supply voltage is used to power the remote sensor. The remote sensor regulates the loop current such that the loop current represents the value of the parameter being measured by the sensor. A series resistor RL at the loop power supply converts this current to a voltage that can be used by the process monitor/controller to record or distribute the parameter being measured.

No Additional Power Required

Easy Wiring

Mining

Automotive

Water

Pulp and Paper

Metals

Pharmaceutical

Utilities

Building services

Technical Specifications

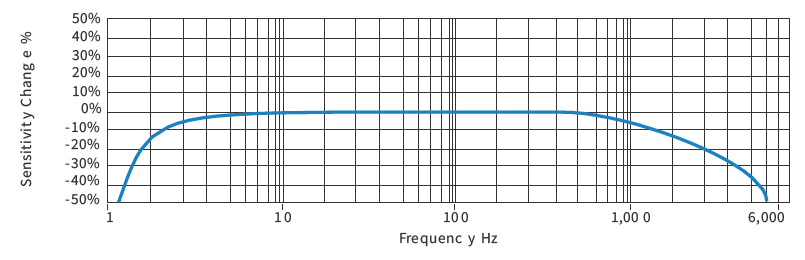

| Mounted Base Resonance | 5kHz min |

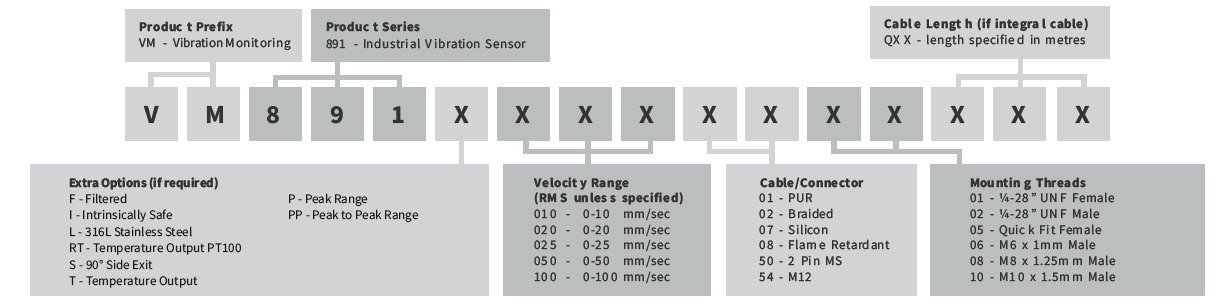

| Velocity Ranges | see: 'How To Order' table ±10% |

| Nominal 80Hz at 22oC | |

| Frequency Response | 10Hz (600cpm) to 1kHz (60kcpm) ± 5% - ISO10816 |

| Isolation | Base isolated |

| Range | 50g peak |

| Transverse Sensitivity | Less than 5% |

Mechanical Specifications

| Case Material | Stainless Steel |

| Sensing Element/Construction | PZT/Compression |

| Mounting Torque | 8Nm |

| Weight | 150gms (nominal) |

| Maximum Cable Length | 1000 metres |

| Standard Cable Length | 5 metres |

| Screened Cable | Braided - length to be specified with order |

| Mounting Threads | see: ‘How To Order ’ table |

Electrical Specifications

| Current Output | 4-20mA DC proportional to Velocity Range |

| Supply Voltage | 15-30 Volts DC (for 4-20mA) |

| Settling Time | 2 seconds |

| Output Impedance | Loop Resistance 600 Ohms max. at 24 Volts |

| Case Isolation | >108 Ohms at 500 Volts |

Environmental Specifications

| Operating Temperature Range | -25 to 90oC |

| Sealing | IP65 |

| Maximum Shock | 5000g |

| EMC | EN61326-1:2013 |

Fans

Motors

Pumps

Compressors

Centrifuges

Conveyors

Air Handlers

Gearboxes

Rolls

Dryers

Presses

Cooling

VAC

Spindles

Machine Tooling

Process Equipment

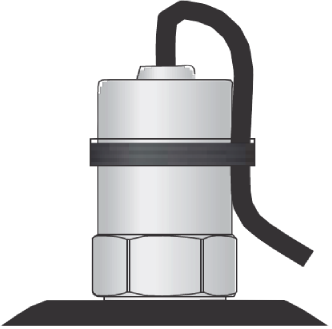

Vibration sensor should be firmly fixed to a flat surface (spot face surface may be needed to be produced and cable anchored to sensor body.)

TAMIL NADU

ANDHRA PRADESH

KARNATAKA

KERALA

TELANGANA

MAHARASHTRA

GOA

GUJARAT

UTTAR PRADESH

DELHI

RAJASTHAN

PUNJAB

HIMACHAL PRADESH

HARYANA

UTTARAKHAND

WEST BENGAL

ODISHA

JHARKHAND

BIHAR

MADHYA PRADESH

CHHATTISGARH