- Ranipet

- Sivakasi

- Karur

- Udhagamandalam

- Hosur

The Artesis AMT Pro is a portable motor driven equipment test system which automatically generates a condition assessment report indicating existing electrical mechanical and operational faults, time to failure information, recommended corrective actions, and effects of faults on energy efficiency.

Rotating Equipment Tester without Sensors

Cloud integration

Advanced analysis and reporting

No sensors on motor or equipment

Immediate payback by corrective action

Improved efficiency and reliability of plant & processes

Increased machine availability

Instant condition assessment report

Access to hard to reach applications

Advanced spectrum and waveform tools

Immediate report generation with actionable information

AMT Pro is compatible with, 3 phase AC Motor of fixed and varibable speed, Generators, Compressors, Fans, Pumps, Conveyors, Motor Driven Equipment

Short test time (7 min)

Live motor testing

Cloud integration (wifi)

Portable, battery powered

Automated Fault Diagnosis

Simple and easy test procedure

Access to hard to reach applications

Advanced spectrum and waveform tools

Immediate report generation with actionable information

Fans

Compressors

AHU

Generators

Mixer

Conveyors

Pumps

Motor Driven Equipment

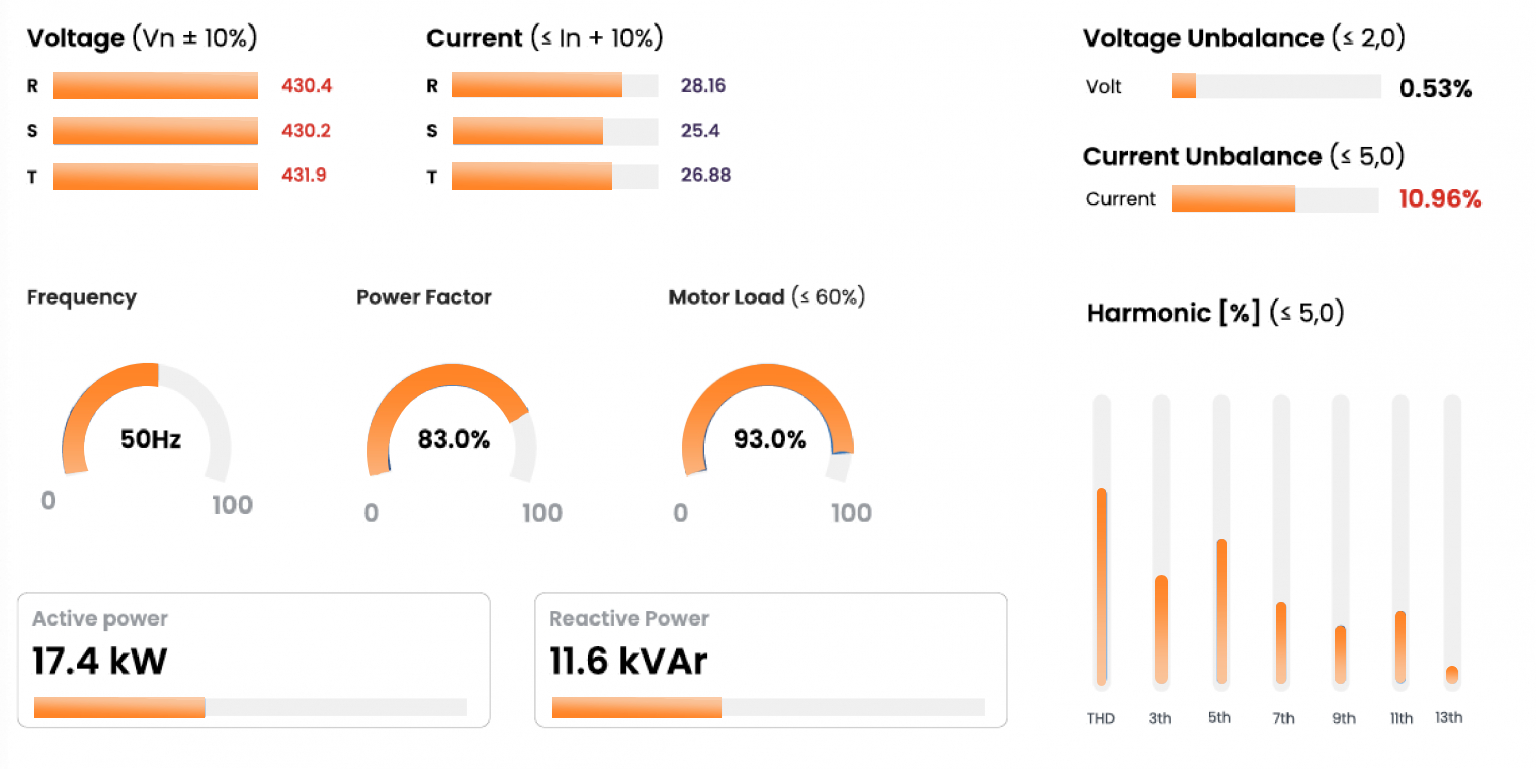

AMT Pro measures 3 phase Voltage and 3 phase current at 2500 Hz sampling rate.Motor tests are completed in 7 minutes. yielding to an automatic test report indicating motor health with barcharts, list of electrical parameters and PSD (Power Spectral Density) results. The test results simultaneously sync to the secure cloud-based server allowing access to the reports on an IoT platform.

Stator

Insulation degradation

Winding looseness

Impedance unbalance or shift

Winding overheating

Phase-to-phase short circuit

Lamination looseness

Loose foot (bolt loose)

Soft foot (stator deformation)

Interturn short circuit (the early phase of turn-to-turn short circuit)

Rotor

Static and dynamic eccentricity

Rubbing

Unbalance (fan, shaft deformation)

Overheating

Damping cage degradation

PM degradation

Severe porosity

Winding looseness

Lamination looseness

Thermal bow (unbalance)

Angular and parallel misalignment

Broken, damaged and loose rotor bars

Bearing

Outer & inner race pitting

Ball/roller wear

Cage/raceway deformation

Cocked bearing

Grease contamination

Over greasing

Bearing creep/skidding

False & true brinelling

Plain bearing oil whirl and whip

Plain bearing radial preload

Plain bearing rotor rub

Machine Faults

Outer & inner race pitting

Ball/roller wear

Cage/raceway deformation

Cocked bearing

Grease contamination

Over greasing

Bearing creep/skidding

False & true brinelling

Plain bearing oil whirl and whip

Plain bearing radial preload

Plain bearing rotor rub

Transmission Faults

Broken teeth/claws

Looseness

Excessive clearance

Eccentricity

Unbalance

Mesh quality

Backlash

Misalignment

Assembly phase problems

Hunting tooth frequency

Process Faults

High energy consumption

Low efficiency

Cavitation in pumps

Flow turbulence in fans, blowers

Filter and heat exchanger fouling

Lubrication

Oversize/undersize motors

TAMIL NADU

ANDHRA PRADESH

KARNATAKA

KERALA

TELANGANA

MAHARASHTRA

GOA

GUJARAT

UTTAR PRADESH

DELHI

RAJASTHAN

PUNJAB

HIMACHAL PRADESH

HARYANA

UTTARAKHAND

WEST BENGAL

ODISHA

JHARKHAND

BIHAR

MADHYA PRADESH

CHHATTISGARH