- Ranipet

- Sivakasi

- Karur

- Udhagamandalam

- Hosur

The Artesis e-MCM is a powerful online condition monitoring, predictive maintenance and power meter tool intended for critical AC rotating equipment. The patented machine learning algorithm of e-MCM enables comprehensive fault detection up to 6 months in advance. With around the clock monitoring and real-time model-based voltage and current analysis, e-MCM can detect electrical, mechanical as well as process faults of fixed, variable speed motors and generators while providing all the benefits without the high complication and cost of traditional systems.

Motor Condition Monitoring Without Sensors

Artesis E-MCM monitors the condition of equipment driven by an electric motor, effectively using the motor itself as a sophisticated transducer and provides clear information for fault detection, diagnostics, time to failure and corrective actions.

Comprehensive Fault Coverage

Online Condition Monitoring

Automated Fault Diagnosis

Onliy Viable Solution for Hard to Reach Motors

Early Fault Detection

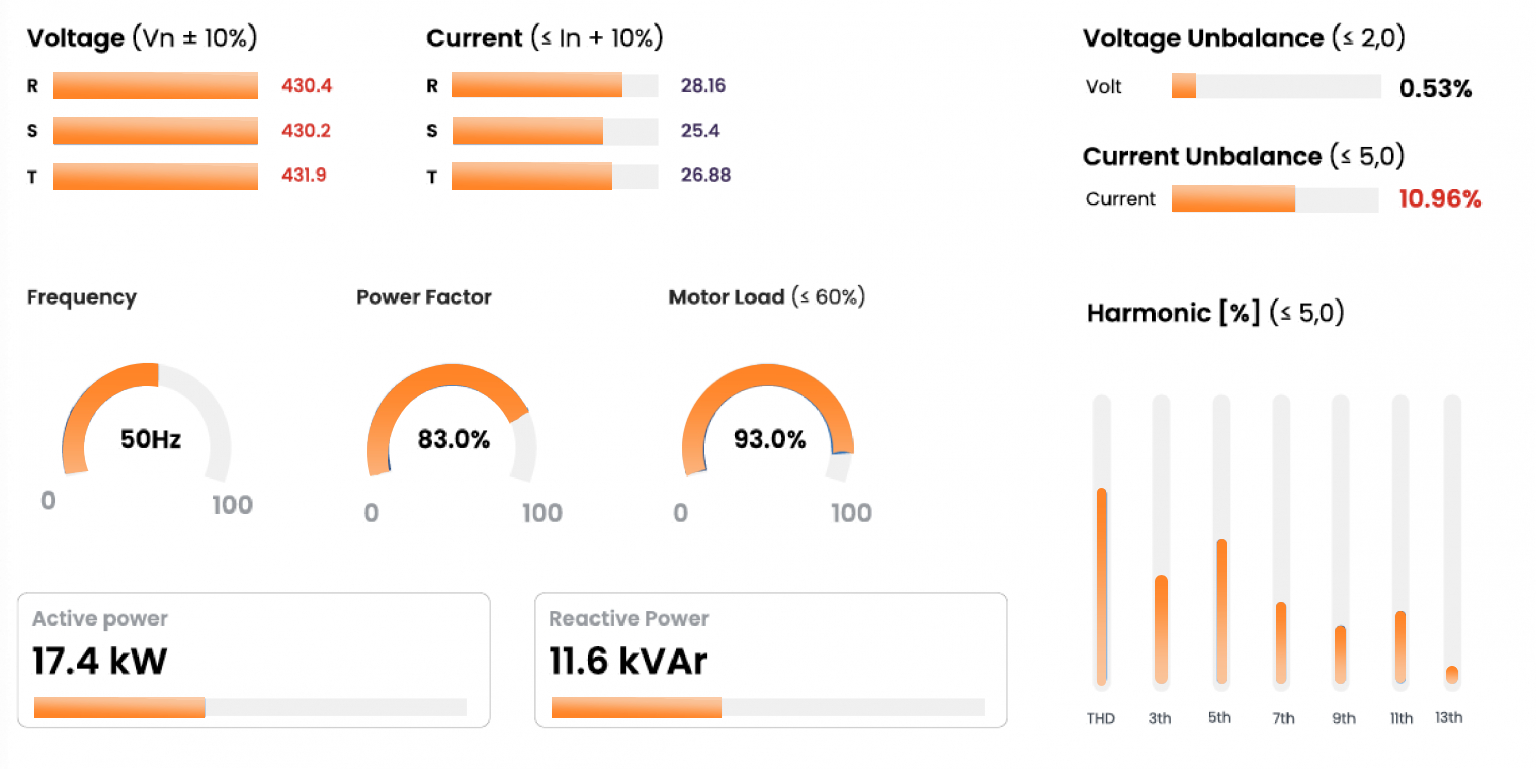

Online Power Monitoring

Award Winning Technology

Effects Of Faults On Energy Efficiency

Ease of Use

The automated fault diagnosis feature of e-MCM makes it very simple to use by the maintenance personnel. Rather than overwhelming the end-user with raw signals and data, e-MCM provides processed data results in an actionable form. The system requires minimal operator intervention for set-up and operation and provides clear indication of the nature and severity of developing faults both locally to the monitored equipment and remotely

Real-Time Monitoring

e-MCM constantly takes measurements and compares them with its reference condition, in order to assess the severity and type of any developing fault. It is able to recognize abnormalities in a wide range of operating states and is even able to extend its self-learning process when it recognizes that it has moved beyond its original learning limits. This allows e-MCM to achieve very sensitive detection of faults without false alarms

Ease of Maintenance Planning

Remote monitoring and reporting services contribute to the development of a sustainable predictive maintenance (PdM) system in the plant without additional workload undertaken by the crew.

Simple Installation

e-MCM installation requires only three-phase voltage and current connection via low-cost current transformers (CT) and voltage transformers (VT) (if needed). It is usually located at the motor control cabinet, requiring very short cable runs and avoiding the need to install equipment in remote or hazardous areas. When first switched on, e-MCM carries out an automatic self-learning process during which the normal operating condition of the equipment is established. Advanced analysis techniques ensure that this training takes account of variables like speed and load, and that existing faults do not result in training errors.

e-MCM monitors your rotating equipment continuously, constantly taking measurements and comparing them with the digital twin it created during the self-learning process. Its unique machine learning algorithm allows it to recognise normal operation in a wide range of conditions, such as different speeds or loads- allowing tight control without false alarms. lf e-MCM identifies a new operating state not experienced during the self-learning phase, it gives you the option of including this state in all future monitoring.

Stator

Interturn short circuit (the early phase of turn-to-turn short circuit)

Phase-to-phase short circuit

Impedance unbalance or shift

Insulation degradation

Soft foot (stator deformation)

Loose foot (bolt loose)

Winding overheating

Winding looseness

Lamination looseness

Rotor

Unbalance (fan, shaft deformation)

Thermal bow (unbalance)

Static and dynamic eccentricity

Rubbing

Severe porosity

Angular and parallel misalignment

Broken, damaged and loose rotor bars

Overheating

Winding looseness

Lamination looseness

Damping cage degradation

PM degradation

Bearing

Outer & inner race pitting

Ball/roller wear

Cage/raceway deformation

Cocked bearing

Grease contamination

Over greasing

Bearing creep/skidding

False & true brinelling

Plain bearing oil whirl and whip

Plain bearing radial preload

Plain bearing rotor rub

Machine Faults

Outer & inner race pitting

Ball/roller wear

Cage/raceway deformation

Cocked bearing

Grease contamination

Over greasing

Bearing creep/skidding

False & true brinelling

Plain bearing oil whirl and whip

Plain bearing radial preload

Plain bearing rotor rub

Transmission Faults

Broken teeth/claws

Looseness

Excessive clearance

Eccentricity

Unbalance

Mesh quality

Backlash

Misalignment

Assembly phase problems

Hunting tooth frequency

Process Faults

High energy consumption

Low efficiency

Cavitation in pumps

Flow turbulence in fans, blowers

Filter and heat exchanger fouling

Lubrication

Oversize/undersize motors

Compressors

Fans

Pumps

Conveyors

Generators

Motor Driven Equipment

AHU

Mixer

TAMIL NADU

ANDHRA PRADESH

KARNATAKA

KERALA

TELANGANA

MAHARASHTRA

GOA

GUJARAT

UTTAR PRADESH

DELHI

RAJASTHAN

PUNJAB

HIMACHAL PRADESH

HARYANA

UTTARAKHAND

WEST BENGAL

ODISHA

JHARKHAND

BIHAR

MADHYA PRADESH

CHHATTISGARH